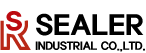

MECHANICAL SEAL CODE

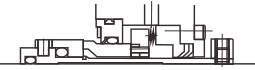

ROTARY PART

| CODE | DRAWING | PACKING | Material | ||

| “S”

SERIES |

S1 | O – Ring | UNBALANCE INSIDE |

MULTI SPRING | |

| S2 | V – PACKING | UNBALANCE INSIDE |

MULTI SPRING | ||

| S3 | O – Ring | BALANCE INSIDE |

MULTI SPRING | ||

| S4 | V – PACKING | BALANCE INSIDE |

MULTI SPRING | ||

| S5 | O – Ring | UNBALANCE INSIDE |

MULTI SPRING | ||

| S6 | WEDGE RING | UNBALANCE INSIDE |

MULTI SPRING | ||

| S7 | O – Ring | BALANCE INSIDE |

MULTI SPRING | ||

| S8 | O – Ring | UNBALANCE DOUBLE |

MULTI SPRING | ||

| S9 | O – Ring | UNBALANCE DOUBLE |

MULTI SPRING | ||

| “M”

SERIE |

M1 | O – Ring | UNBALANCE INSIDE |

MONO SPRING | |

| M21 | V – PACKING | UNBALANCE INSIDE |

MONO SPRING | ||

| M3 | O – Ring | BALANCE INSIDE |

MONO SPRING | ||

| M4 | V – PACKING | BALANCE INSIDE |

MONO SPRING | ||

| M5 | O – Ring | UNBALANCE INSIDE |

MONO SPRING | ||

| M51 | O – Ring | BALANCE INSIDE |

MONO SPRING | ||

| M6 | O – Ring | UNBALANCE INSIDE |

MONO TAPER SPRING | ||

| M61 | O – Ring | UNBALANCE INSIDE |

MONO TAPER SPRING | ||

| M62 | O – Ring | BALANCE INSIDE |

MONO TAPER SPRING | ||

| M63 | O – Ring | BALANCE INSIDE |

MONO TAPER SPRING | ||

| “B”

SERIES |

B1 | O – Ring | UNBALANCE INSIDE |

METAL BELLOWS | |

| B2 | WEDGE RING | UNBALANCE INSIDE |

METAL BELLOWS | ||

| “C”

SERIES |

C1 | O – Ring | UNBALANCE OUTSIDE |

MULTI SPRING | |

| C2 | O – Ring | BALANCE INSIDE |

MULTI SPRING | ||

| C3 | WEDGE RING | UNBALANCE OUTSIDE |

MULTI SPRING | ||

| C4 | O – Ring | UNBALANCE OUTSIDE |

MULTI SPRING | ||

| C5 | O – Ring | UNBALANCE INSIDE |

MULTI SPRING | ||

| “SC”

SERIES |

SC |  |

O – Ring | SINGLE CARTRIDGE | MULTI SPRING |

| SC2 |  |

O – Ring | DOUBLE CARTRIDGE | MULTI SPRING | |

| SCR |  |

O – Ring | DOUBLE CARTRIDGE | MULTI SPRING | |

| “CB”

SERIES |

CB1 |  |

O – Ring | DOUBLE CARTRIDGE | MULTI SPRING |

| CB2 |  |

O – Ring | SINGLE CARTRIDGE | MULTI SPRING | |

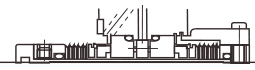

STATIONARY PART

| TYPE | DRAWING | PACKING | TYPE |

| A |  |

O – Ring | CARBON SOLID SIC SOLID T/C |

| A1 |  |

O – Ring | SOLID SIC SOLID T/C S/C INSERT T/C INSERT CERAMIC COAT T/C COAT |

| A2 |  |

O – Ring | SOLID SIC SOLID T/C S/C INSERT T/C INSERT CERAMIC COAT T/C COAT |

| A3 |  |

PACKING | SOLID SIC SOLID T/C S/C INSERT T/C INSERT CERAMIC COAT T/C COAT |

| C |  |

O – Ring | CARBON SOLID SIC SOLID T/C |

| C1 |  |

O – Ring | SOLID SIC SOLID T/C S/C INSERT T/C INSERT CERAMIC COAT T/C COAT |

| C2 |  |

O – Ring | CARBON SIC INSERT T/C INSERT CERAMIC COAT T/C COAT |

| C3 |  |

O – Ring | CARBON SIC INSERT T/C INSERT CERAMIC COAT T/C COAT |

| L |  |

O – Ring | CARBON SIC INSERT CERAMIC T/C INSERT |

| M |  |

O – Ring | SIC INSERT T/C INSERT CERAMIC COAT T/C COAT |

| M1 |  |

O – Ring | SIC INSERT T/C INSERT CERAMIC COAT T/C COAT |

| M2 |  |

CUP RUBBER | CERAMIC SOLID SIC SOLID T/C |

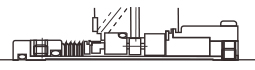

MATERIAL PART

| Part of Face | Code | |

| Face Materials Zone | Carbon | A |

| Stellite Coat | B | |

| Ceramic(AI2O3) | C | |

| Ceramic Coating | D | |

| Solid T/C | E | |

| T/C Plate | F | |

| SIC Plate | G | |

| Solid SIC | H | |

| T/C Coat | I | |

| Special | S |

| Part of Packing | Code | |

| Packing Meterials Zone |

Viton | V |

| E.P.R | E | |

| N.B.R | N | |

| Teflon | T | |

| Kalrez | K | |

| Perfluoro | F | |

| F.E.P | B | |

| Teflon Carbon | C | |

| Graphite | D |

| Part of Body | Code | |

| Face Materials Zone | STS304 | L |

| STS316 | M | |

| STS316L | N | |

| Carpenter 20 | C | |

| Hastelloy B | I | |

| Hastelloy C | H | |

| Titanium | T | |

| Monel Alloy | O | |

| Inconel | P | |

| 17-4 PH | Q |

MECHANICAL SEAL SELECTION

| Rating | Model | |

| Liquid | Clean Water & Seal Water Waste Water & Slurry Refining Petrochemical Industry Pulp & Paper Industry Metal Industry |

S1, S5, M1, M5, M6 M1, M5, M6 S1, S6, S8, S9, C1, SCR+Sub Part M1, M5, SC, SCR+Sub Part S1, S5, S6, S8, S9, C1, C3 |

| Pressure | Max 10 kgf / cm² Max 30 kgf / cm² High Pressure |

S1, M1, All Model S3, M3, M5, M62 S3A, M3A Tandem, SCR+Sub Part |

| Speed | Max 3600 rpm Over 3600 rpm |

All Model Within Size 80 All Model + Special Type |

| Temperature | Max 150 °C Max 250 °C Over 250 °C |

All Model All Model + Sub Part Special + Sub Part |