MIXER SEAL

In chemical, pharmaceutical, food and oil refining plants, various equipment is used for agitation, dilution and blending of a Fluid. these units need a reliability and safety for protect the environment and workplace. Mechanical Seal can move to an axial or a radial of the Shaft, Mechanical Seal must provide excellent performance in the units.

- Liquid Lubricated, Dry Contacting or Non Contacting Face technology

- The Modular designs for easy part replacement

- The Cartridge designs with or without a bearing

- Top and side installation method

- The Sealing system to withstand the Inversion Phenomenon of Pressure and can handle emergency situations

- Cooling Flange Option

- Designs is comply with the major standards of OEM

- Designs is comply with the major standards of DIN

- Ability to handle the Run out of axial and radial

- Materials selected for corrosion resistance and life of Mechanical Seal

- The Split designs for easy installation

- The Sterilization designs

- Auxiliary system to enhance reliability

- Support from Knowledgeable and experienced the Mixer Seal Team

- Designs complies Customer Need

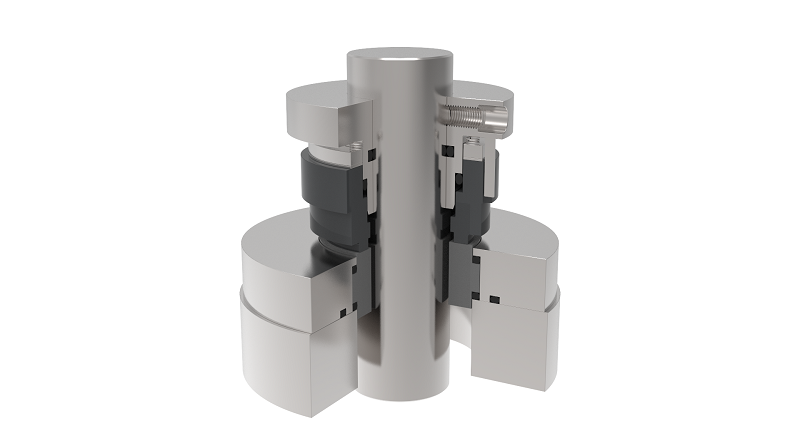

SSU5

SSU2

SD2

SD1

-

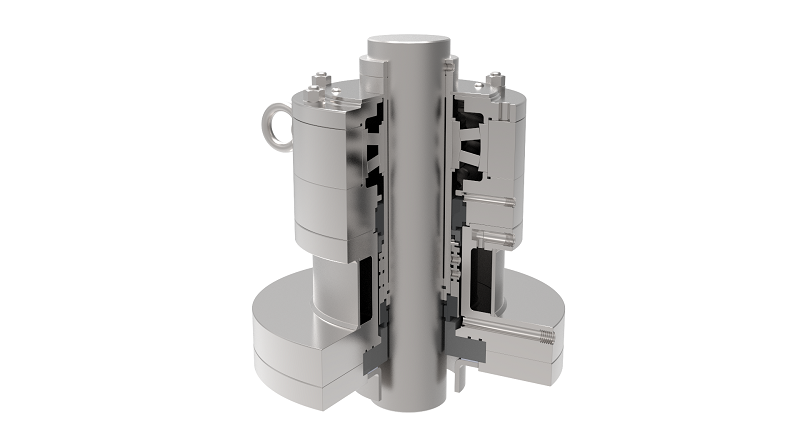

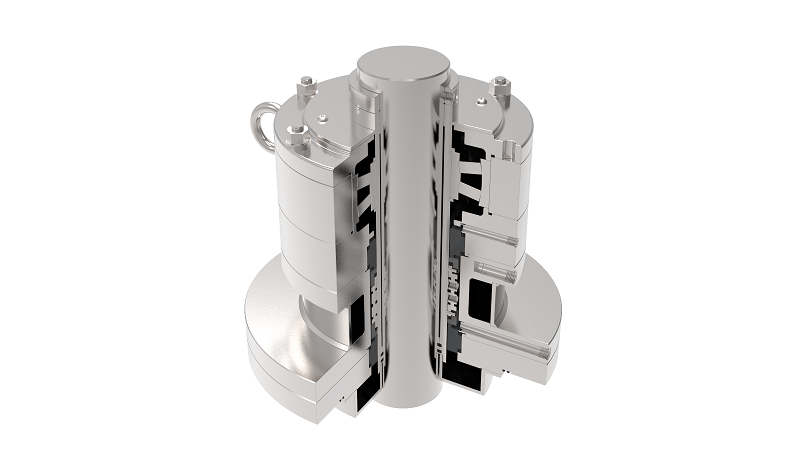

SSU5

The modular SSU series is based on the standard of Din, uses the components of Liquid Seal. the SSU5 uses a Double Liquid Seal. it is designed for Glass Lined Vessel that contained a bearing.

-

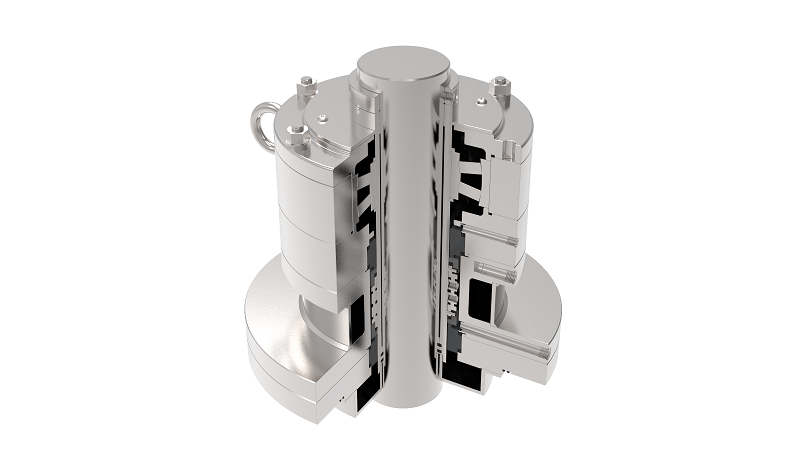

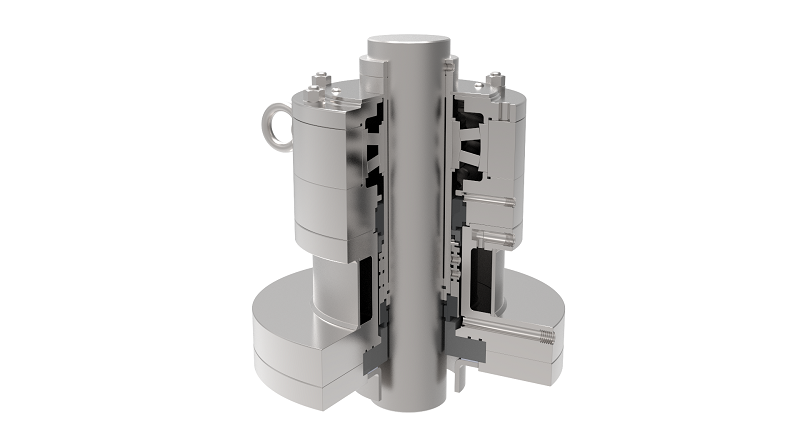

SSU2

The modular SSU series is based on the standard of Din, uses the components of Liquid Seal. the SSU2 uses a Double Liquid Seal. it is designed for Steel Vessel that contained a bearing. -

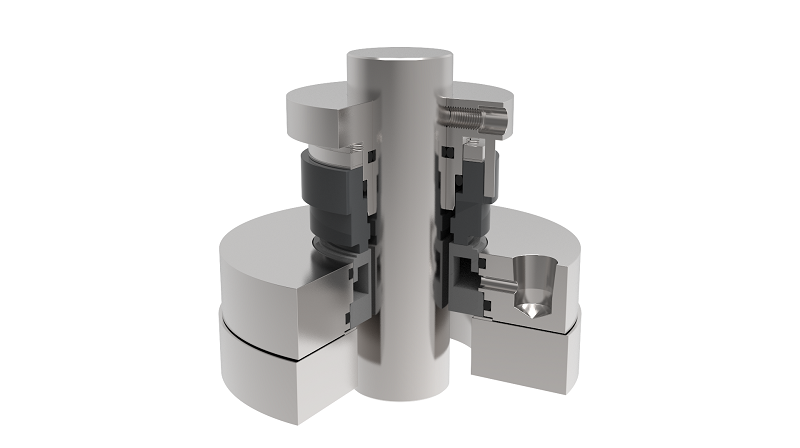

SD2

It is same model of series with SD1. but it is designed to use for high temperature than SD1. -

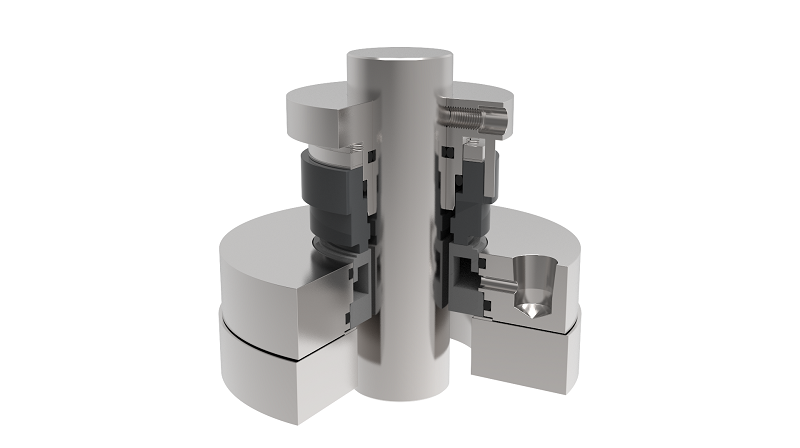

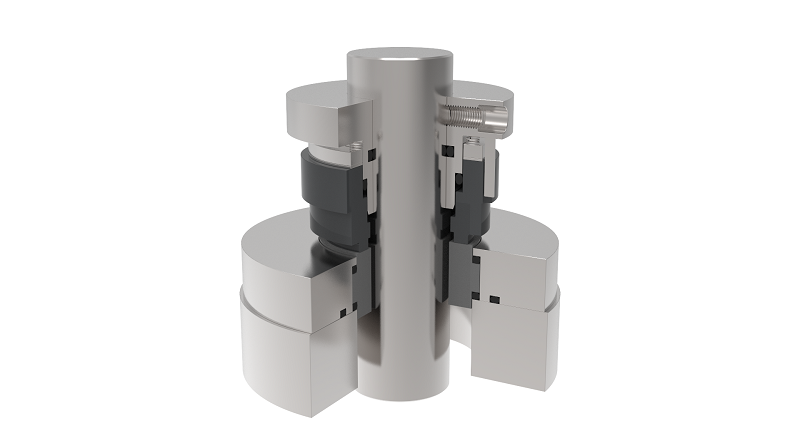

SD1

The Single, Outside and Dry Running Pusher Seal specifically designed suitable for equipment of Top Entry Agitator. these are can be used to equipment that is 0.150” (3.8mm) TIR eccentricity because of greater strength structure of Mixer Seal. It does not need the Buffer Fluid System. a milled slot and a mating pin can distribute torque to the Seal face for prevent excessive the Stress.