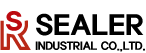

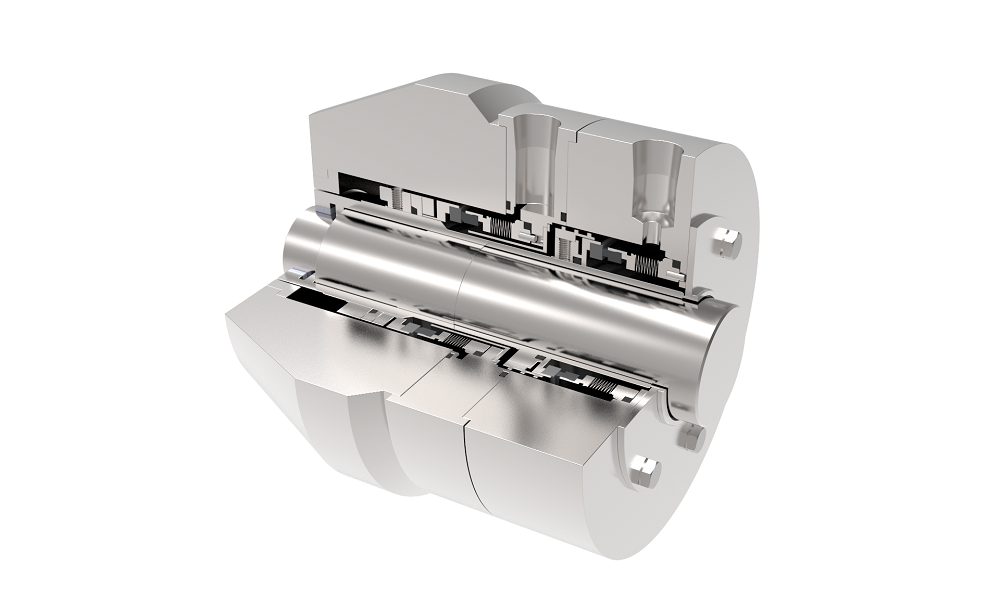

METAL BELLOWS CARTRIDGE

METAL BELLOWS TYPE

SCB1

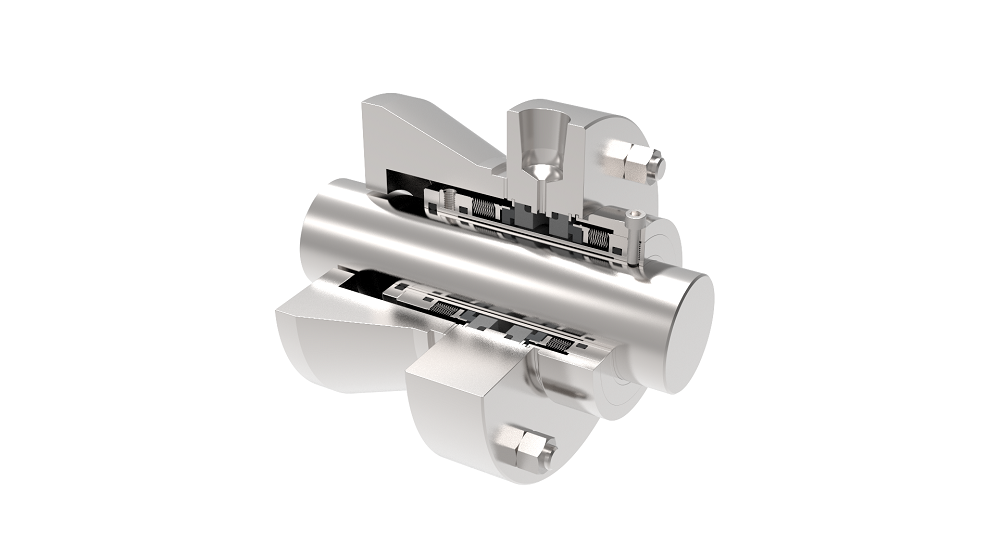

SCBA

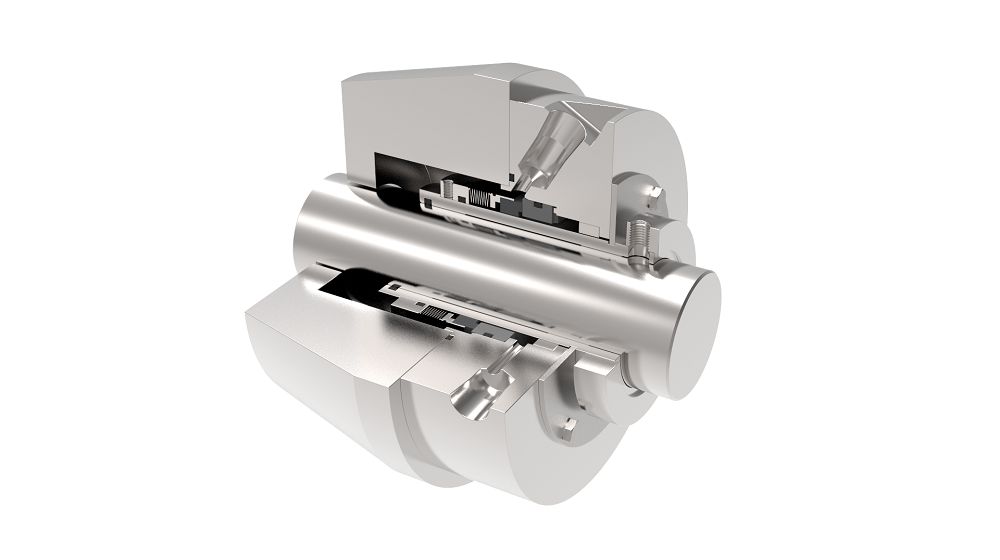

SCBT1

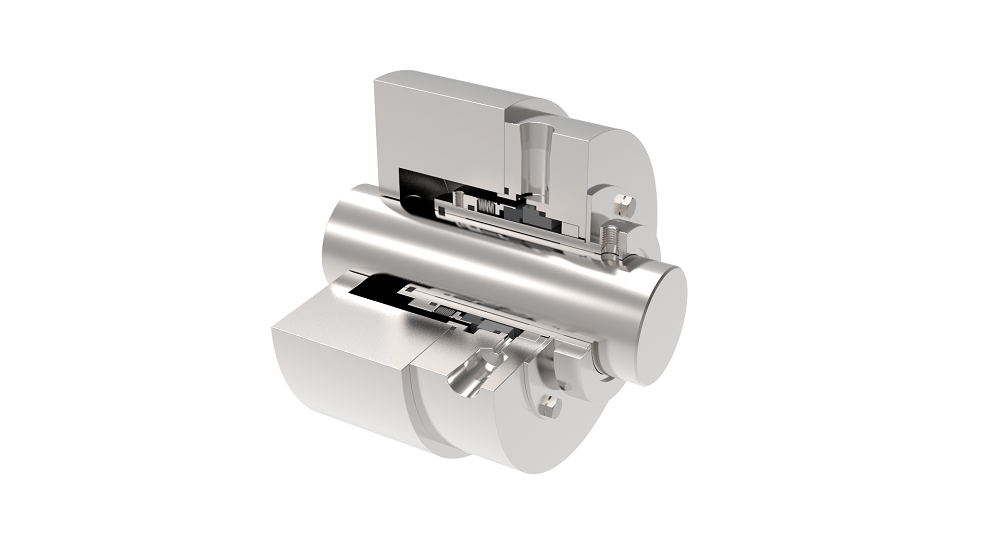

SCB3

SCB4

SCBT3

SCBT4

CB1

CB2

-

METAL BELLOWS TYPE

The Single, Balanced, Welded Rotation Metal and Bellows Seal designs are used to oil refining, petrochemical and chemical industry. the Standard SCB1 Seal uses a Stainless Bellows, but can uses a Hastelloy Bellows. these are comply all requirements of API 682 Type B. the Bellows is rotating and it provides Self Cleaning effect which prevents solids from entering the Bellows Convolution.

The Bellows Seal is overcomes many of problems associated with Pusher Seal. it can prevents Hang UP phenomenon that is made by pile up of solids or gasket swell due to absence of Dynamic Gasket. the rotating Bellows Seal has the benefit of Self Cleaning effect, disposing of particles or solids through centrifugal force. some Bellows Seal are not dependent on Elastomer or PTFE, it can withstand higher temperatures than Pusher Seal. also the Grafoil can be used, which has an excellent temperature range and chemical resistance. Bellows Seal has fewer parts than others. that is why it is easier to install.

However Bellows Seal is not suitable for high pressures since the Bellows Diaphragm is relatively thin. Bellows Seal has less inherent Damping Action, Boundary Lubrication with Stick Slip conditions such as with Light Hydrocarbon can generate vibration leading to Fatigue Failure. the complicated manufacturing process restricts Bellows Seal sizes.

■ Advantages ■

+ No Dynamic Gasket

+ Excellent temperature range

+ Fewer parts and easier to install

■ Disadvantages ■

- Not for high pressure

- Not for low Specific Gravity of fluid

-

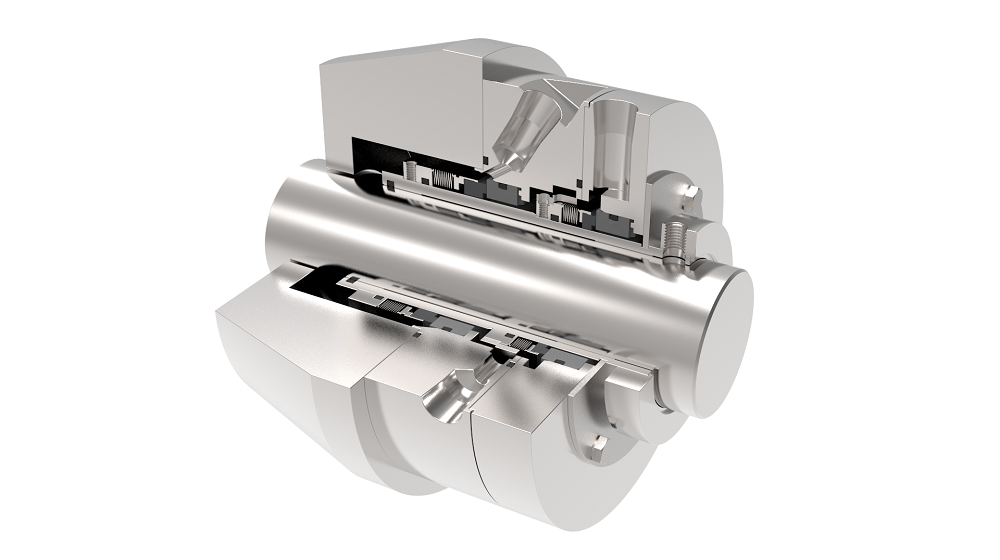

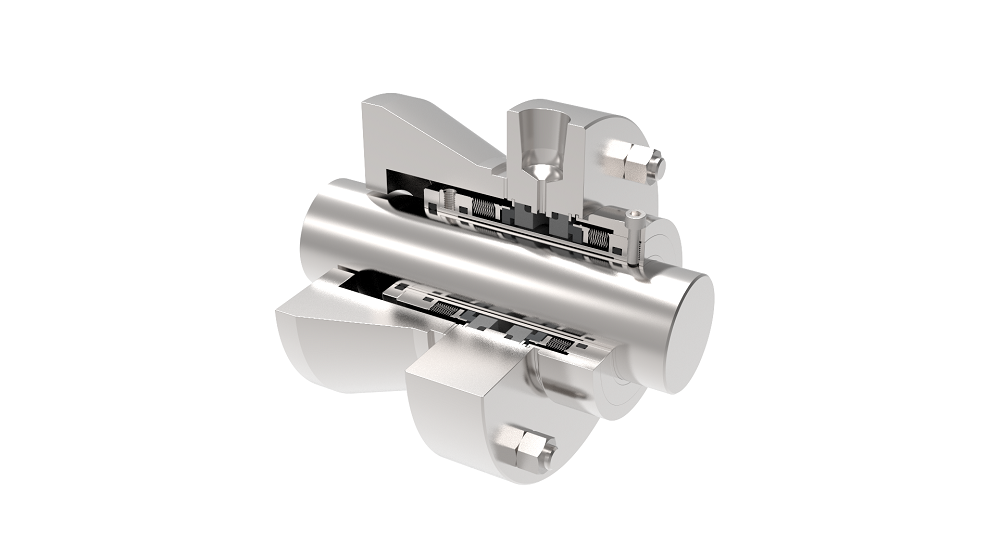

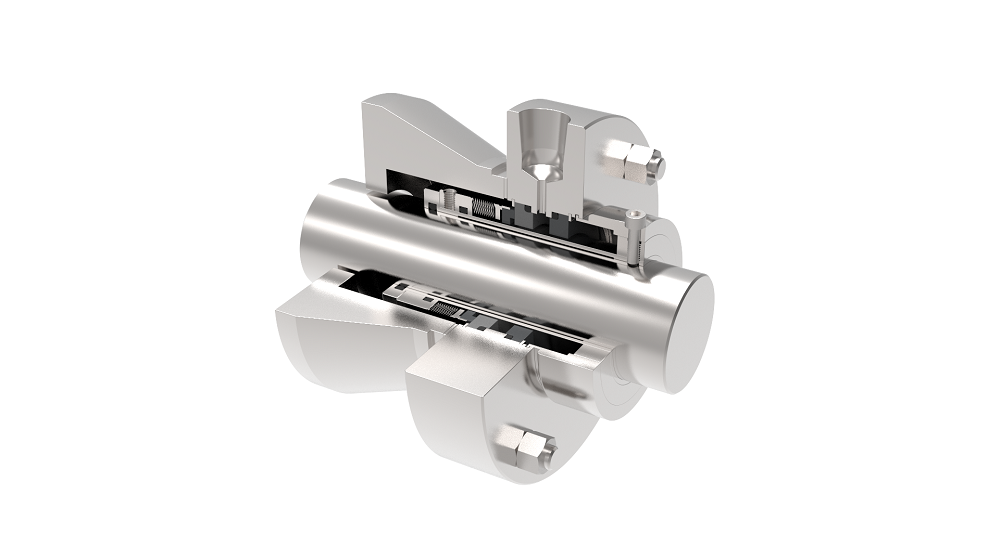

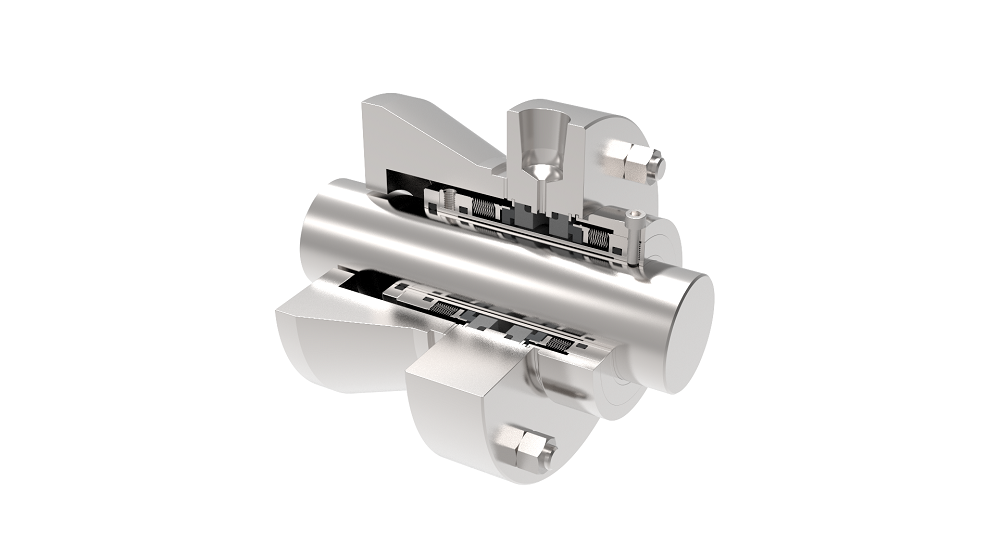

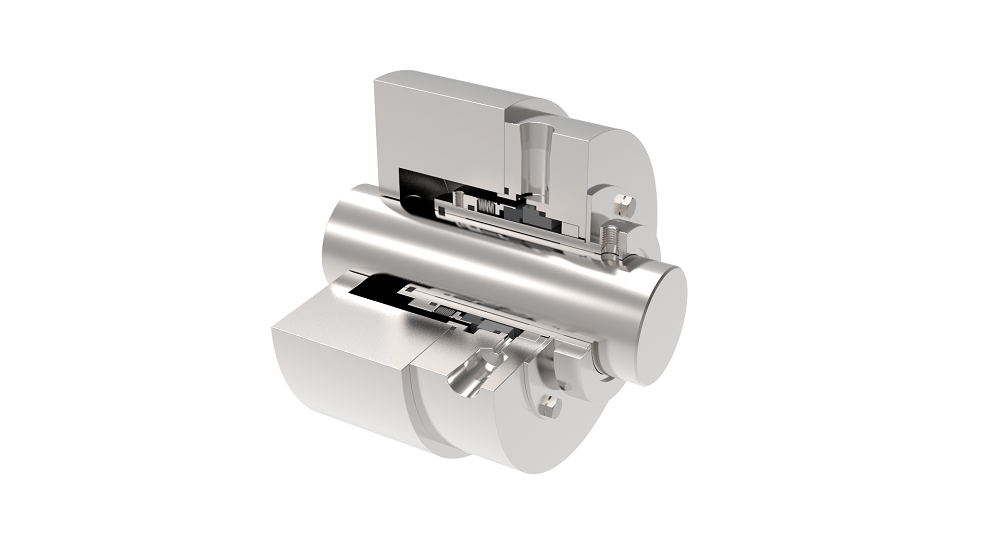

SCB1

The Single, Balanced, Welded Rotation Metal and Bellows Seal designs are used to oil refining, petrochemical and chemical industry. the Standard SCB1 Seal uses a Stainless Bellows, but can uses a Hastelloy Bellows. these are comply all requirements of API 682 Type B. the Bellows is rotating and it provides Self Cleaning effect which prevents solids from entering the Bellows Convolution.

The Bellows Seal is overcomes many of problems associated with Pusher Seal. it can prevents Hang UP phenomenon that is made by pile up of solids or gasket swell due to absence of Dynamic Gasket. the rotating Bellows Seal has the benefit of Self Cleaning effect, disposing of particles or solids through centrifugal force. some Bellows Seal are not dependent on Elastomer or PTFE, it can withstand higher temperatures than Pusher Seal. also the Grafoil can be used, which has an excellent temperature range and chemical resistance. Bellows Seal has fewer parts than others. that is why it is easier to install.

However Bellows Seal is not suitable for high pressures since the Bellows Diaphragm is relatively thin. Bellows Seal has less inherent Damping Action, Boundary Lubrication with Stick Slip conditions such as with Light Hydrocarbon can generate vibration leading to Fatigue Failure. the complicated manufacturing process restricts Bellows Seal sizes.

■ Advantages ■

+ No Dynamic Gasket

+ Excellent temperature range

+ Fewer parts and easier to install

■ Disadvantages ■

- Not for high pressure

- Not for low Specific Gravity of fluid

-

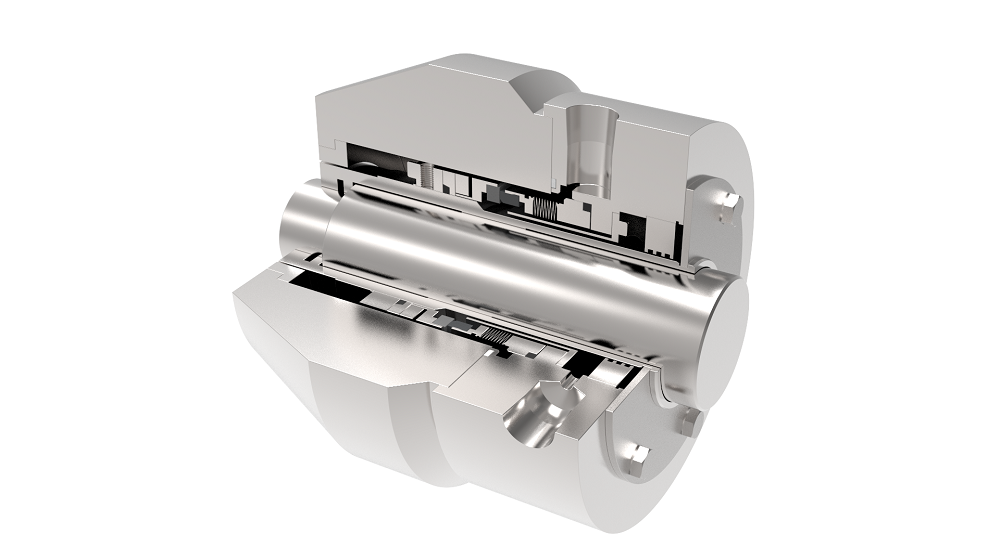

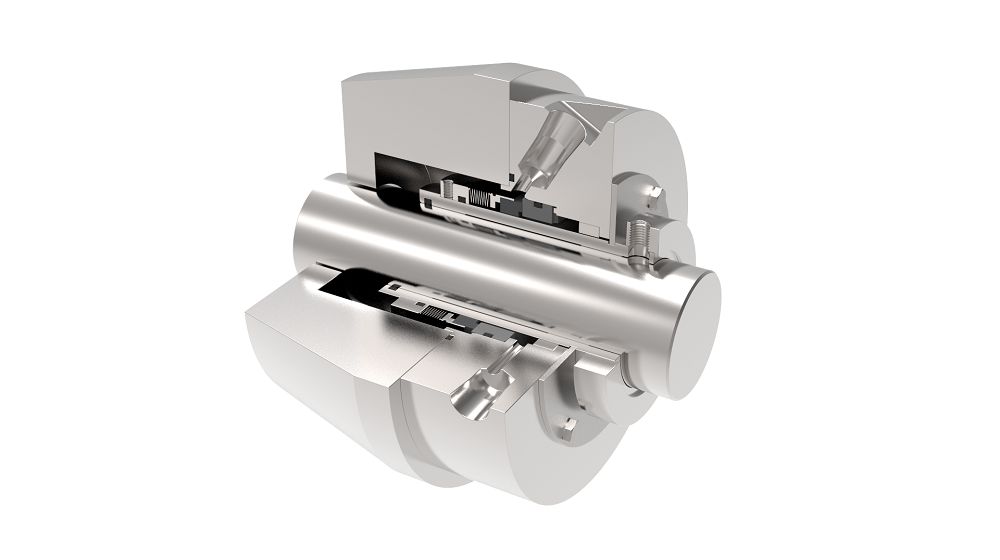

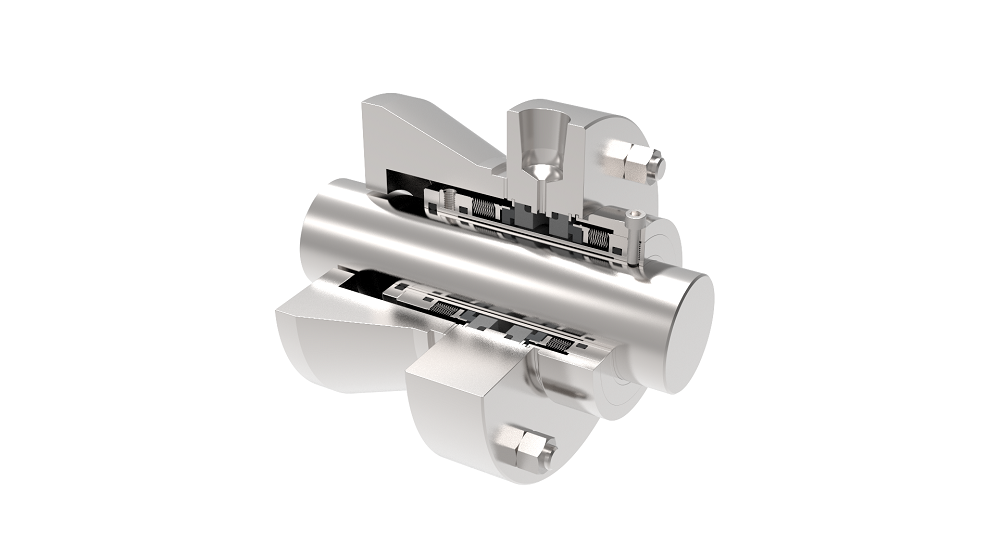

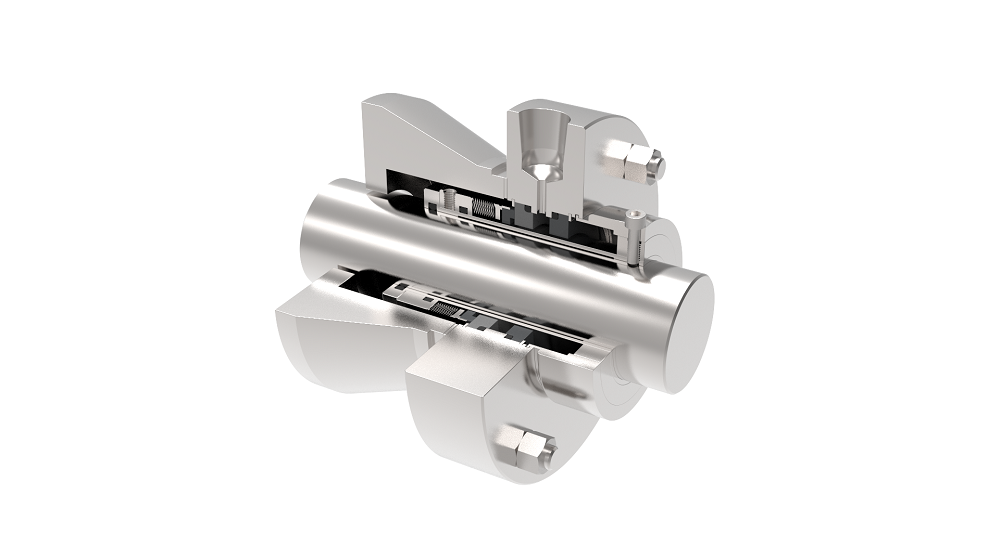

SCBA

The Single and Rotating Metal Bellows designs are eliminate Hang Up or Fretting in the Shaft Packing, these are used to oil refining and chemical industry. the Seal Ring is easily and economically replaced. the Centroid Loaded Face Attachment methods increase life of Seal by preventing Seal Face distortion caused by different thermal expansion rates of the Seal and END Flange. Cartridge designs available. also it is used to most ANSI Pumps. -

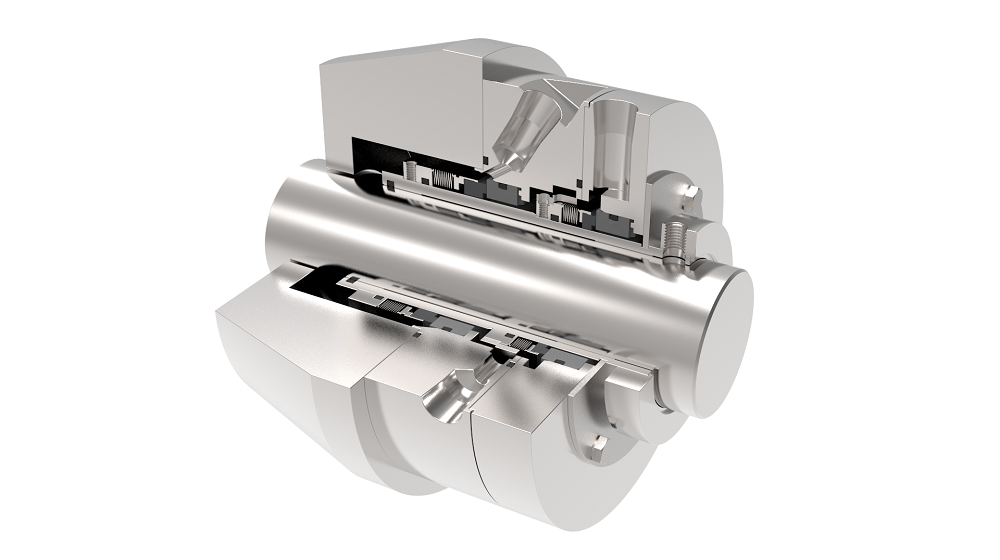

SCBT1

The Double, Tandem, Balanced, Welded Rotating Metal Bellows Seal and SCBT1 designs are used to oil refining, petrochemistry and chemical industry. these are use a 316 Bellows, but can use a Alloy C-276 Bellows. also perfectly comply Arrangement 3 of API 682 Type A. it provides Self Cleaning effect which prevents solids from entering the Bellows Convolution. it use the Pumping Ring to the Out Part Rotor for circulate the Sealant. -

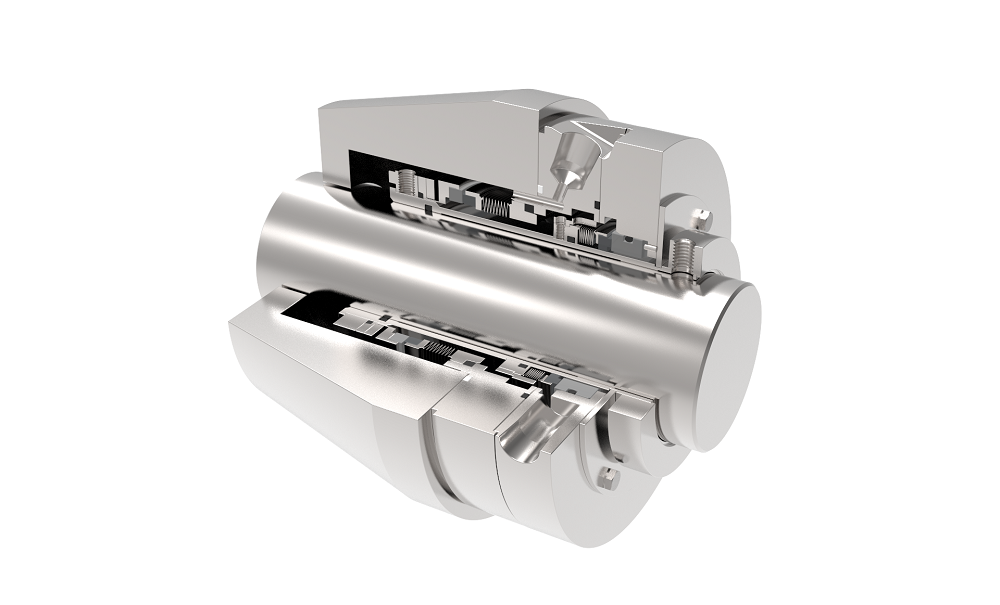

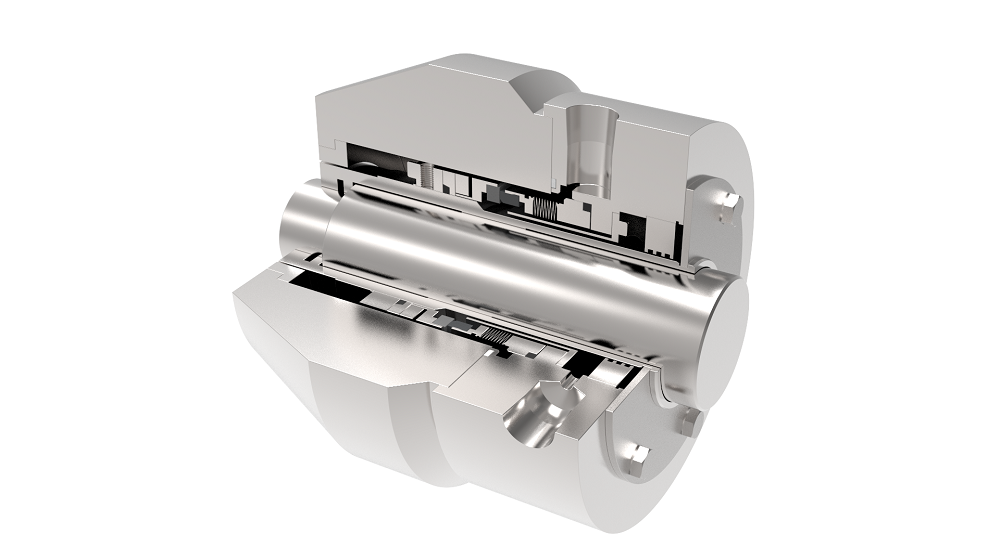

SCB3

The Single, Balanced, Welded Stationary Metal Bellows Seal designs are used to oil refining, petrochemistry and chemical industry. it is less sensitive for Alignment or Perpendicularity since use the Stationary Bellows Seal. also it is used to high speed. -

SCB4

The Single, Balanced and Welded Stationary Alloy 718 Bellows Seal designs are used to the high temperature petrochemical equipment. these are satisfy all requirements of API 682 Type C. it use an Alloy 718 material and a Low Stress Bellows design to improve the corrosion resistance. the Shrinkage fitting of the Stationary Face design minimize distortion of Seal and allows low leakage and low abrasion under a wide operating range. it is less sensitive for Alignment or Perpendicularity since use the Stationary Bellows Seal. also it is used to high speed.

-

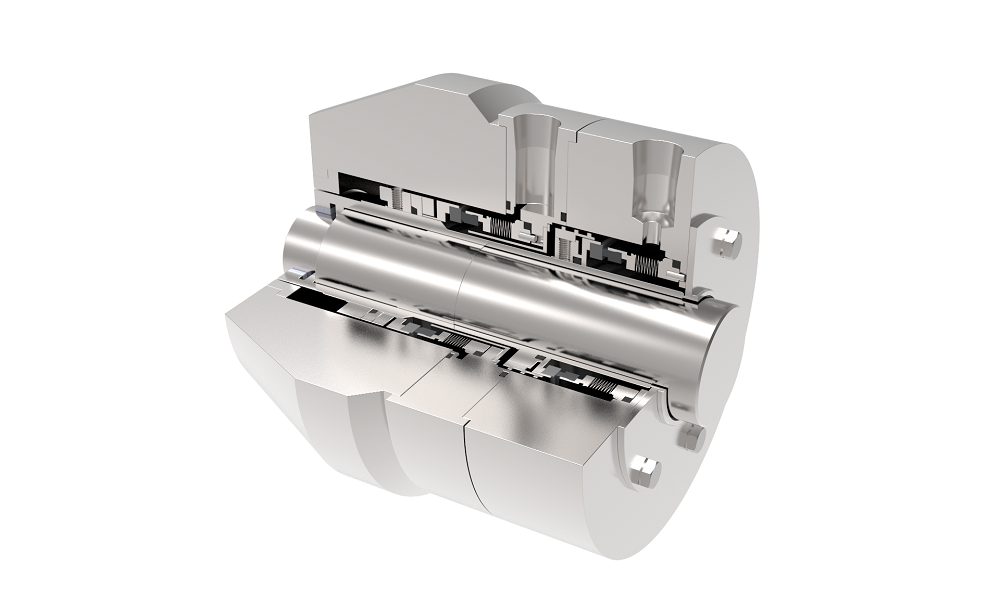

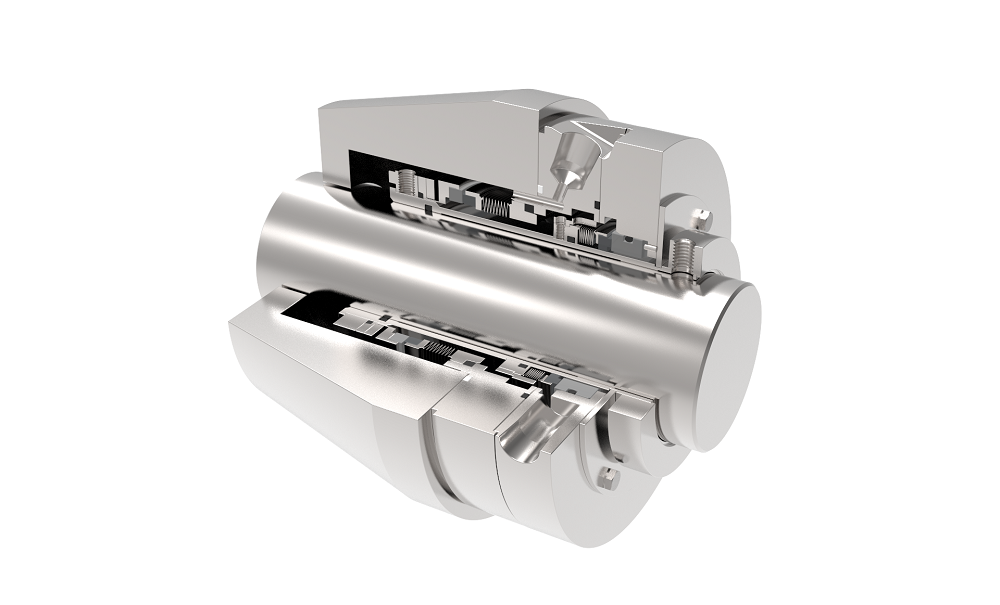

SCBT3

The Double, Tandem, Balanced and Welded Stationary Metal Bellows Seal designs are used to oil refining, petrochemistry and chemical industry. it is less sensitive for Alignment or Perpendicularity since use the Stationary Bellows Seal. it is used to high speed. also perfectly comply Arrangement 3 of API 682 Type A. it use the Pumping Ring to the Out Part Rotor for circulate the Sealant. -

SCBT4

The Double, Tandem, Balanced and Welded Stationary Alloy 718 Bellows Seal are used to the high temperature petrochemical equipment. these are perfectly comply Arrangement 3 of API 682 Type A. it use an Alloy 718 material and a Low Stress Bellows design to improve the corrosion resistance. it is less sensitive for Alignment or Perpendicularity since use the Stationary Bellows Seal. it is used to high speed. also it use the Screw Ring to the Out Part Rotor for circulate the Sealant. -

CB1

STANDARD -

CB2

STANDARD