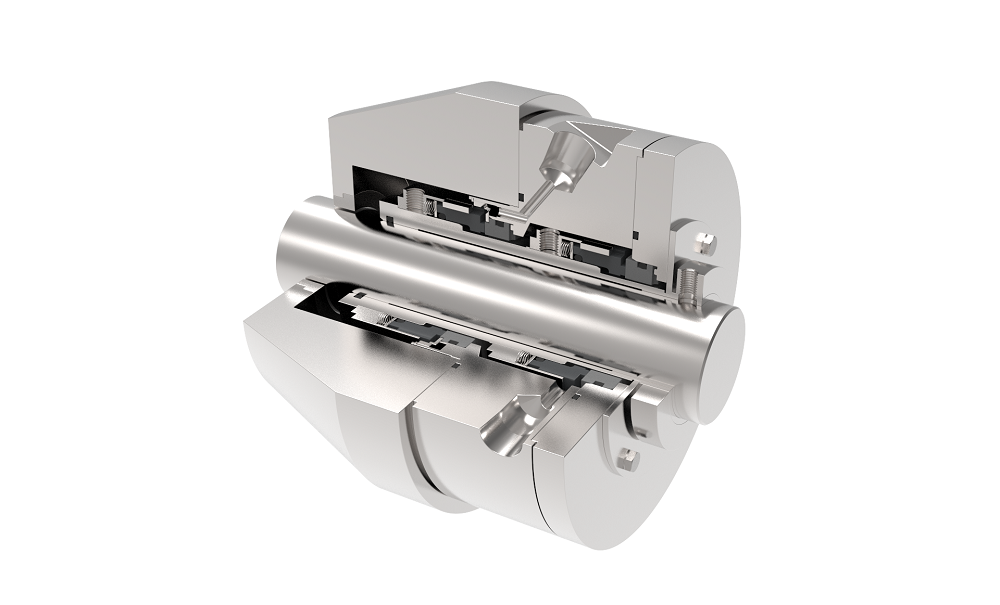

PUSHER CARTRIDGE

PUSHER TYPE

CS1A

CS3A

CM8A

CS7M

CS7MT

CS8MT

-

PUSHER TYPE

The Single, Balanced, Welded Rotation Metal and Bellows Seal designs are used to oil refining, petrochemical and chemical industry. the Standard SCB1 Seal uses a Stainless Bellows, but can uses a Hastelloy Bellows. these are comply all requirements of API 682 Type B. the Bellows is rotating and it provides Self Cleaning effect which prevents solids from entering the Bellows Convolution.

The Bellows Seal is overcomes many of problems associated with Pusher Seal. it can prevents Hang UP phenomenon that is made by pile up of solids or gasket swell due to absence of Dynamic Gasket. the rotating Bellows Seal has the benefit of Self Cleaning effect, disposing of particles or solids through centrifugal force. some Bellows Seal are not dependent on Elastomer or PTFE, it can withstand higher temperatures than Pusher Seal. also the Grafoil can be used, which has an excellent temperature range and chemical resistance. Bellows Seal has fewer parts than others. that is why it is easier to install.

However Bellows Seal is not suitable for high pressures since the Bellows Diaphragm is relatively thin. Bellows Seal has less inherent Damping Action, Boundary Lubrication with Stick Slip conditions such as with Light Hydrocarbon can generate vibration leading to Fatigue Failure. the complicated manufacturing process restricts Bellows Seal sizes.

■ Advantages ■

+ General purpose

+ Lower cost

+ High pressure

+ High speed

+ The Damping Action of Dynamic Gasket : Suitable for Light Hydrocarbon

■ Disadvantages ■

- Gasket material and temperature limitations

- Can be more sensitive for Hang Up depending on equipment

-

CS1A

The Low Pressure Single, Unbalanced, Multi Spring Seal are used to chemical industry. each parts are easier to replace and completely interchangeable with each other. These Seals can be used in abrasion and corrosion equipment as an Inside Seal or Outside Seal. The CS1A complies all requirements of API 682 Type A. -

CS3A

The High Pressure Single, Balanced, Multi Spring Seal are used to general equipment industry. each parts are easier to replace and completely interchangeable with each other. it is widely used for high pressure.

-

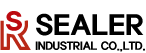

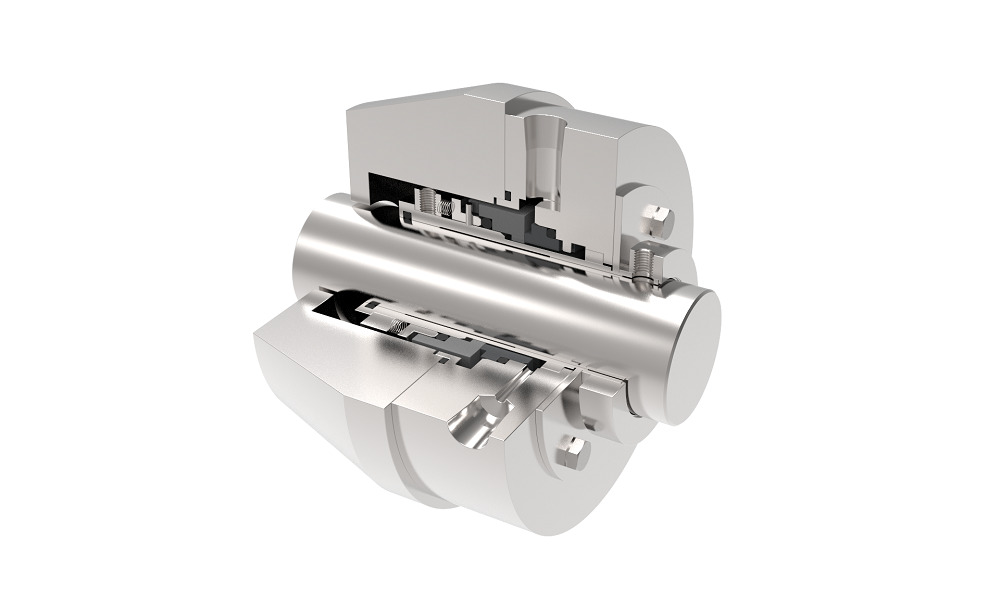

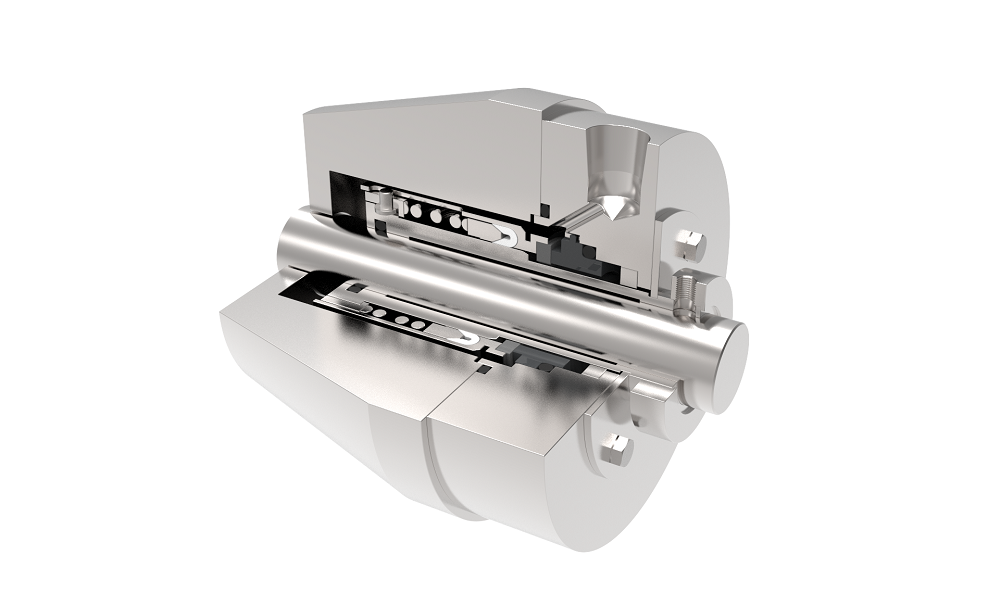

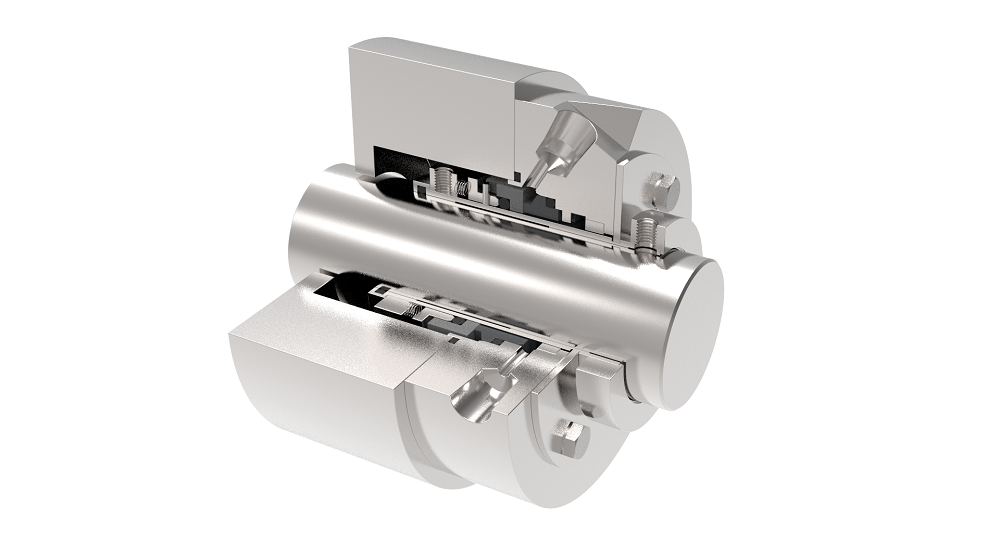

CM8A

The Single, Balanced, Rotating, Single Spring Seal are used to Heavy Duty or general equipment. the CM8A Seal use a Graphite Gasket that encapsulated by high technology and Silicon Carbide Rotar for prevent a misalignment of shaft and bearing. the Canned Face of the Seal has little leak by keeping a best flatness of Seal Face. -

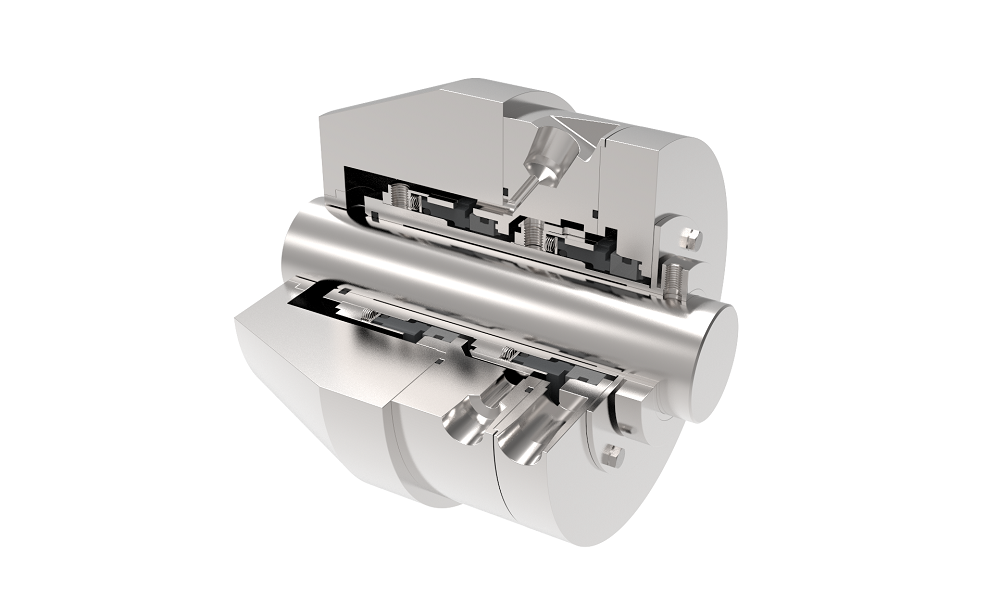

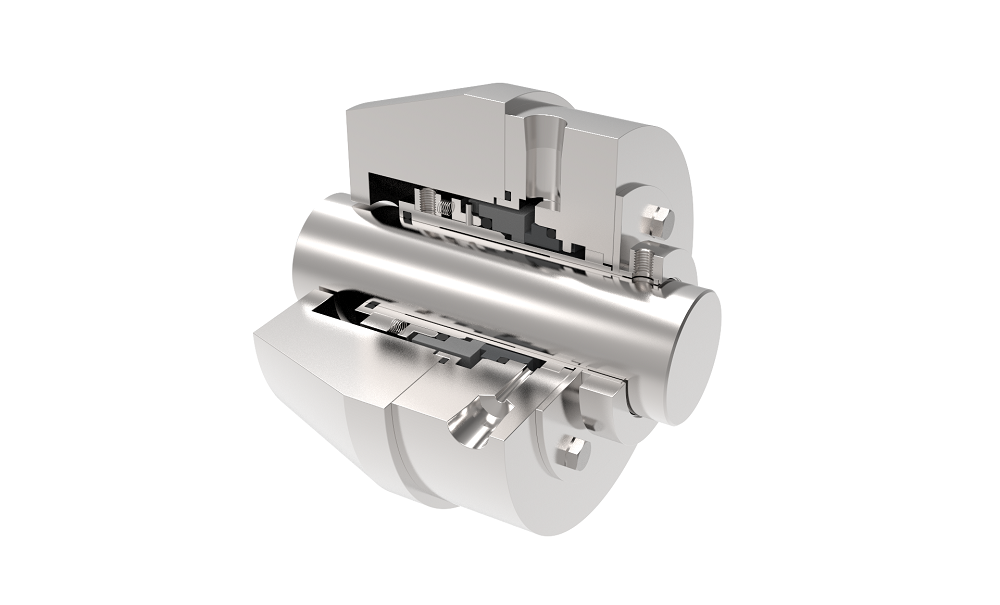

CS7M

The Single, Balanced, Multi Spring, Pusher Seal are used to petrochemistry and petroleum industry. the CS7M complies all requirements of API 682 Type A. -

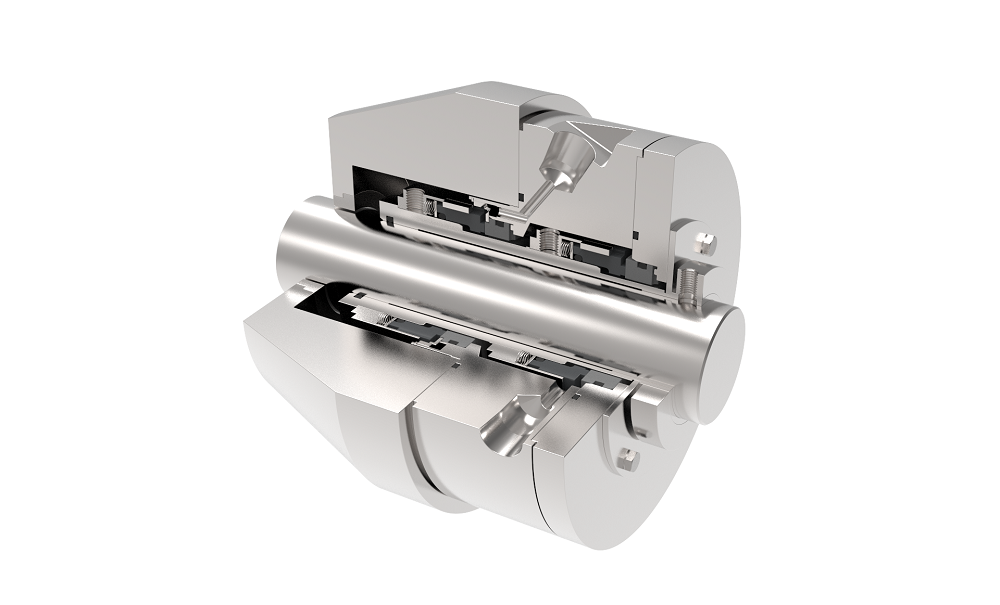

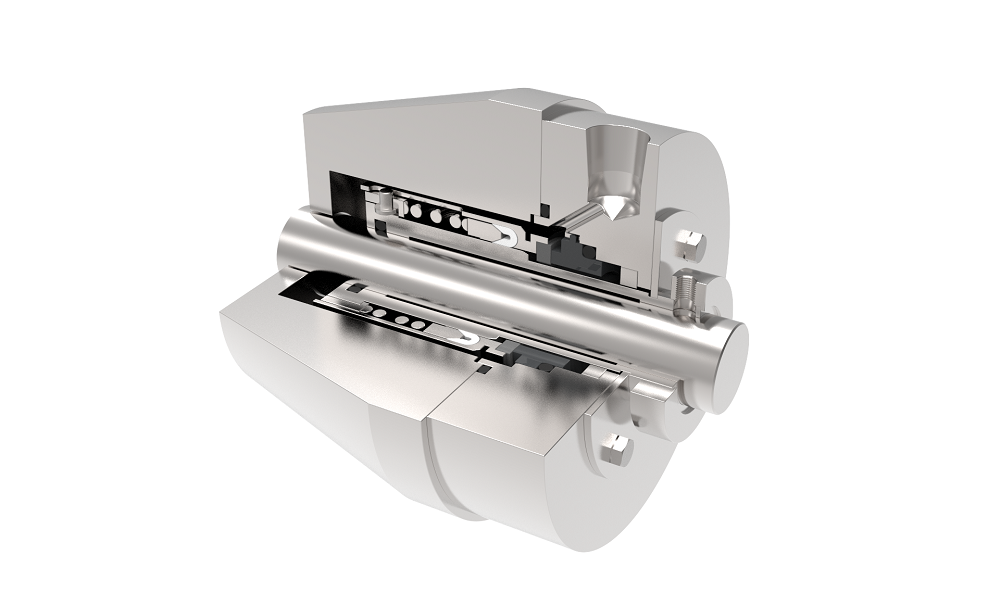

CS7MT

The CS7MT is designed to withstand the Inversion Phenomenon of Pressure. it has a more wide limit of pressure and complies Arrangement 3 of API 682 Type A. it use the Pumping Ring to the Out Part Rotor for circulate the Sealant.

-

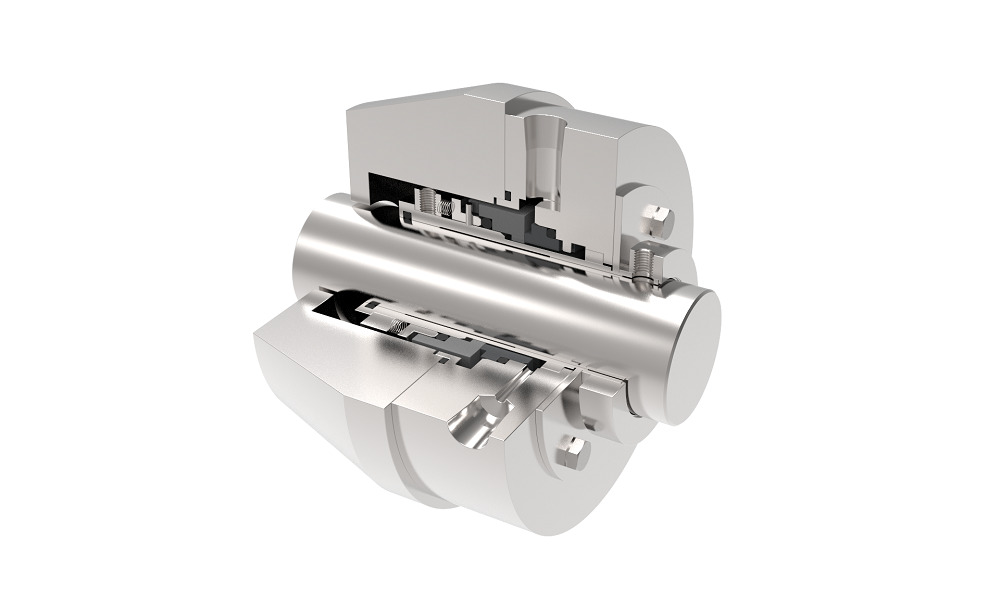

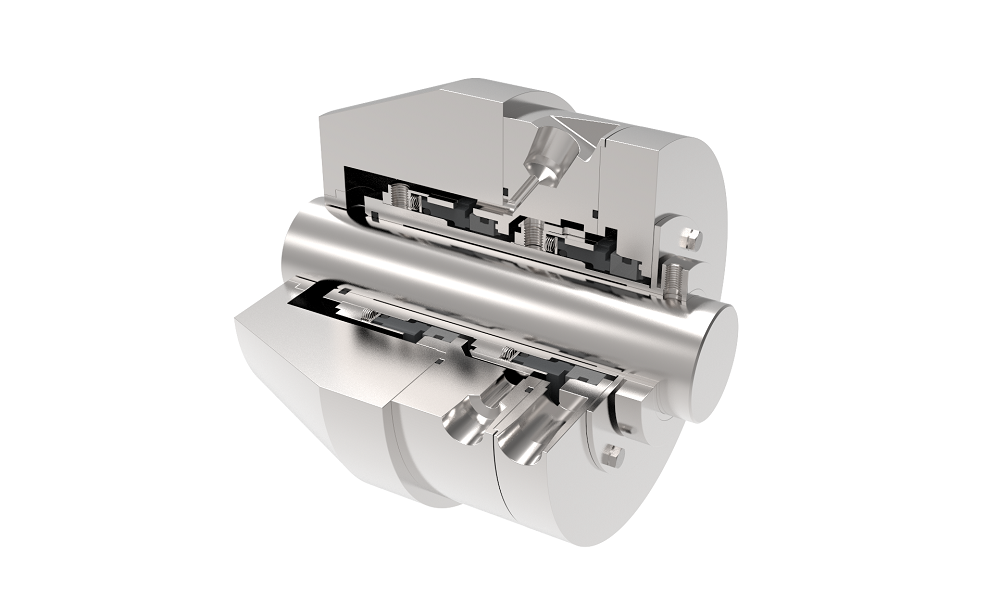

CS8MT

The CS8MT is designed to withstand against the Inversion Phenomenon of Pressure. it has a more wide limit of pressure and complies Arrangement 3 of API 682 Type A.