SLURRY CARTRIDGE

SLURRY TYPE

CSS1

CSS2

SF1

-

SLURRY TYPE

The Single, Balanced and Multi Spring Seal are have a Springs at outside for avoid piled up the slurry on Springs. material of Face is Silicon Carbide. It has a tidy design, greater strength structure and enough space between Seal and Shaft Sleeve. a fluid without the slurry can use more wide operating range.

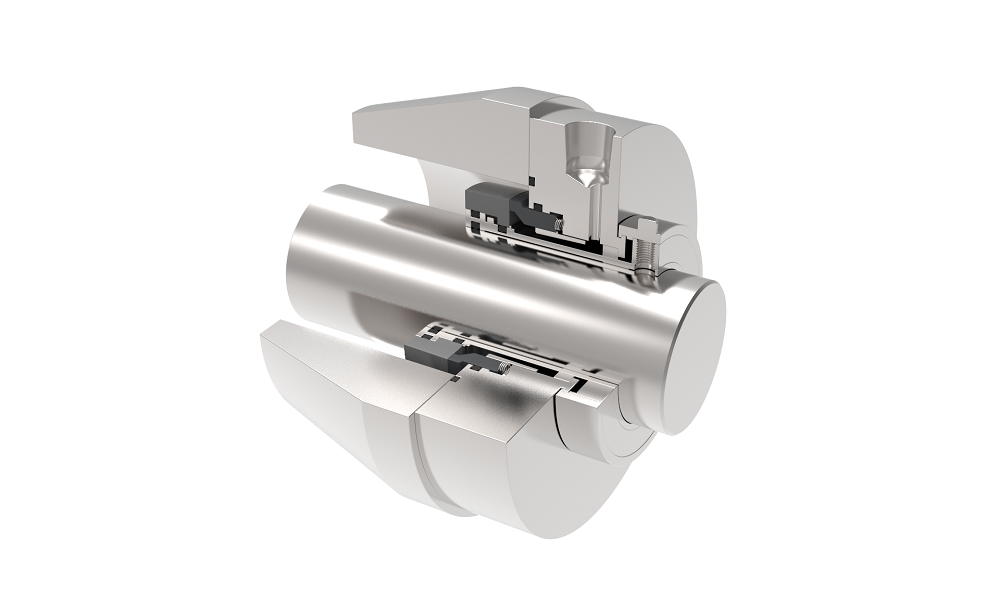

The Single, Balanced, Multi Spring, Cartridge, Pusher Seal specifically designed suitable to Slurry that contained Paper and Pulp. it is made as unique design that is expose a Seal face to the Pumping fluid for divide the heat. it can solve the problem about heat. special Shroud Seal is made for prevent pile up the solid on the Rotor Drive Pin and Springs in the Stationary portion. it is easier to install by Cartridge design or Centering Tabs.

The Double, Pusher, Multi Balanced Seal specifically designed suitable to Slurry that contained Paper and Pulp. special Shroud Seal is made for prevent pile up the solid on the Rotor Drive Pin and Springs in the Rotary portion. it is easier to install by Cartridge design or Centering Tabs.

-

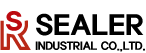

CSS1

The Single, Balanced and Multi Spring Seal are have a Springs at outside for avoid piled up the slurry on Springs. material of Face is Silicon Carbide. It has a tidy design, greater strength structure and enough space between Seal and Shaft Sleeve. a fluid without the slurry can use more wide operating range. -

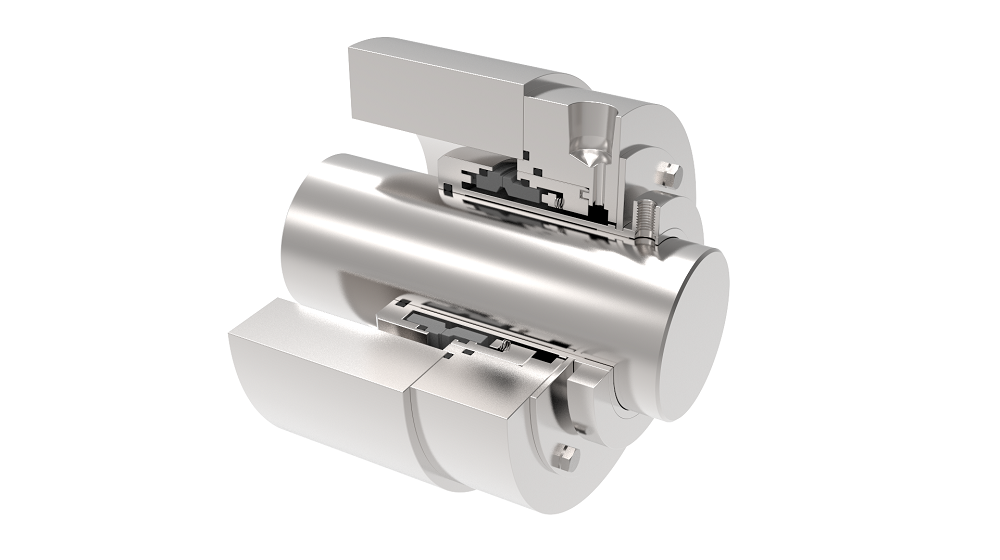

CSS2

The Single, Balanced, Multi Spring, Cartridge, Pusher Seal specifically designed suitable to Slurry that contained Paper and Pulp. it is made as unique design that is expose a Seal face to the Pumping fluid for divide the heat. it can solve the problem about heat. special Shroud Seal is made for prevent pile up the solid on the Rotor Drive Pin and Springs in the Stationary portion. it is easier to install by Cartridge design or Centering Tabs.

-

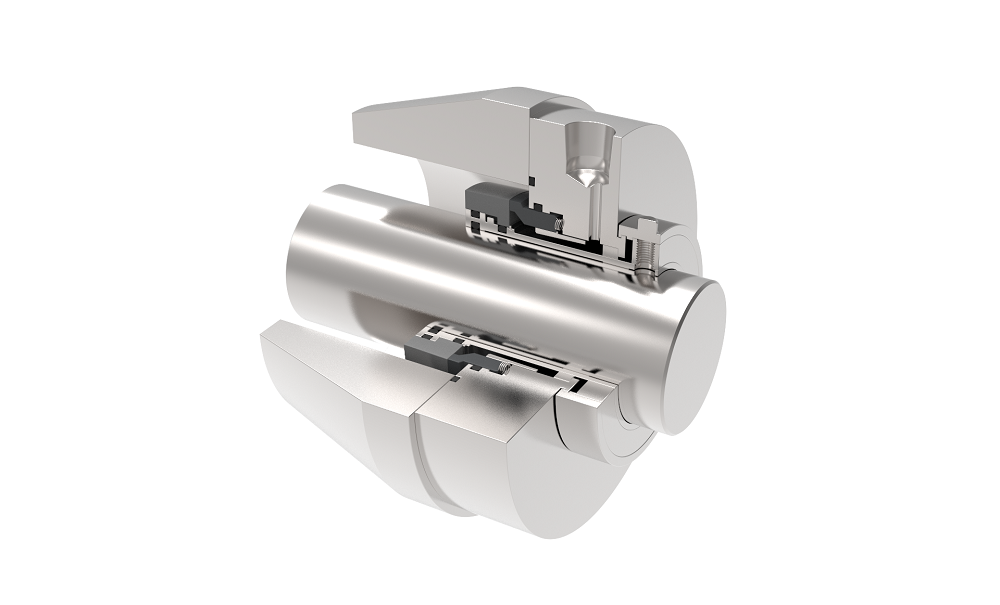

SF1

The Double, Pusher, Multi Balanced Seal specifically designed suitable to Slurry that contained Paper and Pulp. special Shroud Seal is made for prevent pile up the solid on the Rotor Drive Pin and Springs in the Rotary portion. it is easier to install by Cartridge design or Centering Tabs.