SPECIAL DUTY SEAL

SBR1

SBR2

SHS

SCBT1

SCBT3

SCBT4

CS7MT

CS8MT

-

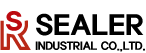

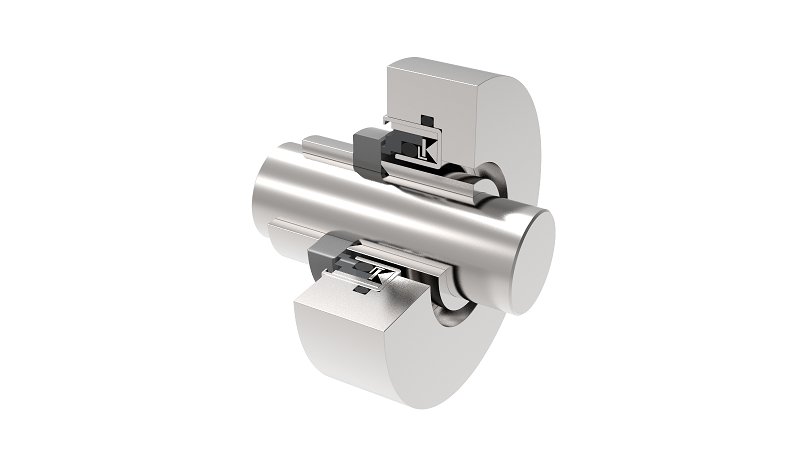

SBR1

The Single and Pusher Seal for pump of Sundyne®.

-

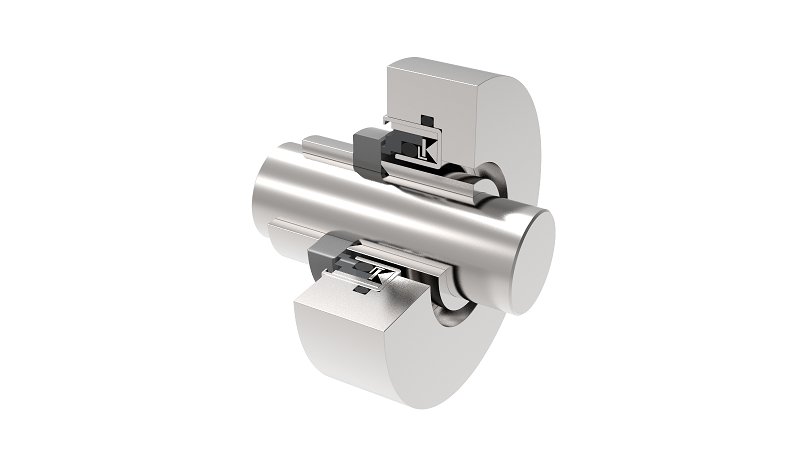

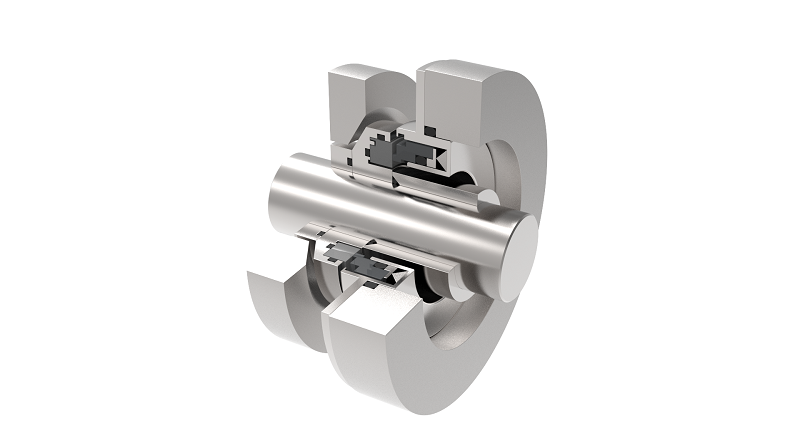

SBR2

The Gas Lubricate Wavy Face Non Contacting Pusher Seal uses the Contained Silicon Carbide Face. it has a lowest Face distortion by Finite Element Analysis to get more wide operating range with highest reliability and lower leakage than limit. also available with PTFE Dynamic Gasket that is supported by springs.

-

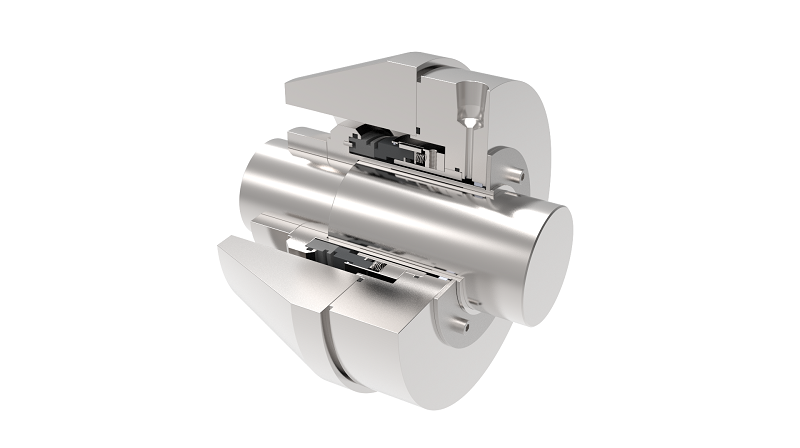

SHS

The Balanced, Flexible Element, Multi Spring Pusher Designs are used to high pressure and high temperature equipment. these are use Boundary Lubrication method for life of Seal.

-

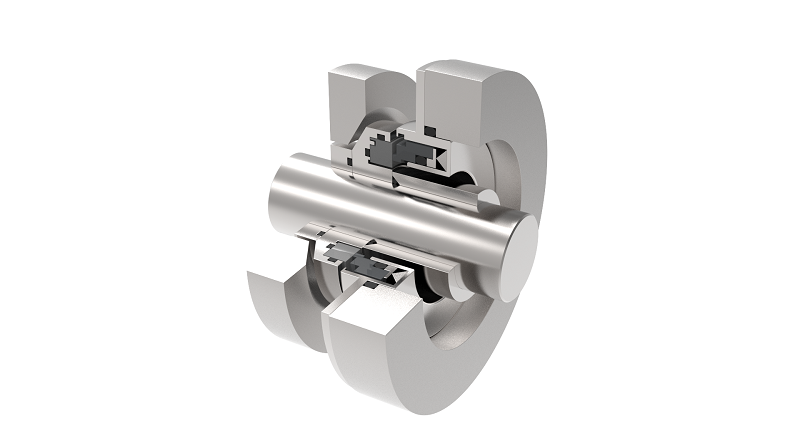

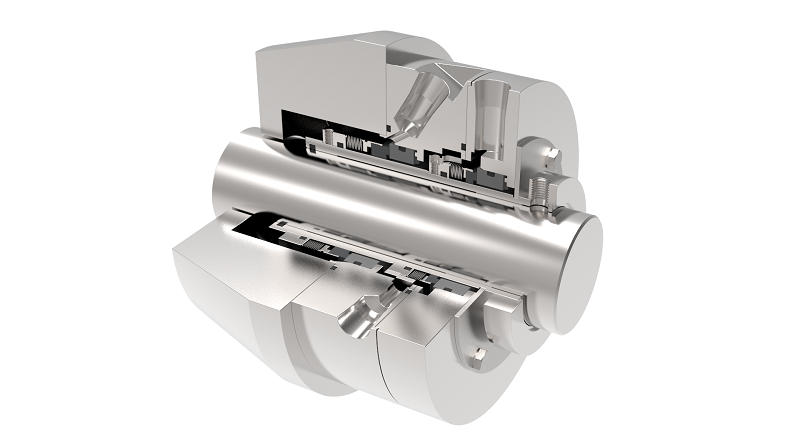

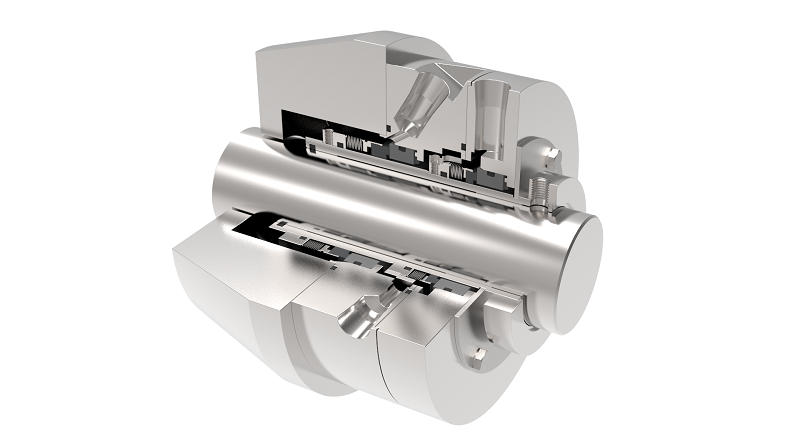

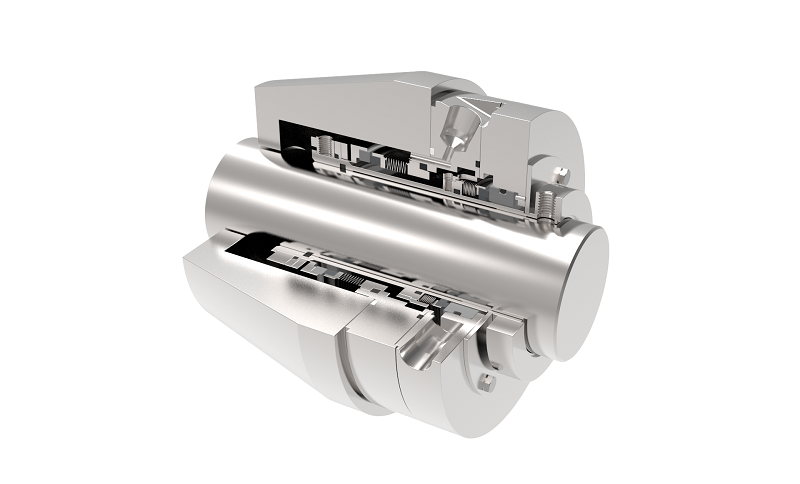

SCBT1

The Double, Tandem, Balanced, Welded Rotating Metal Bellows Seal and SCBT1 designs are used to oil refining, petrochemistry and chemical industry. these are use a 316 Bellows, but can use a Alloy C-276 Bellows. also perfectly comply Arrangement 3 of API 682 Type A. it provides Self Cleaning effect which prevents solids from entering the Bellows Convolution. it use the Pumping Ring to the Out Part Rotor for circulate the Sealant.

-

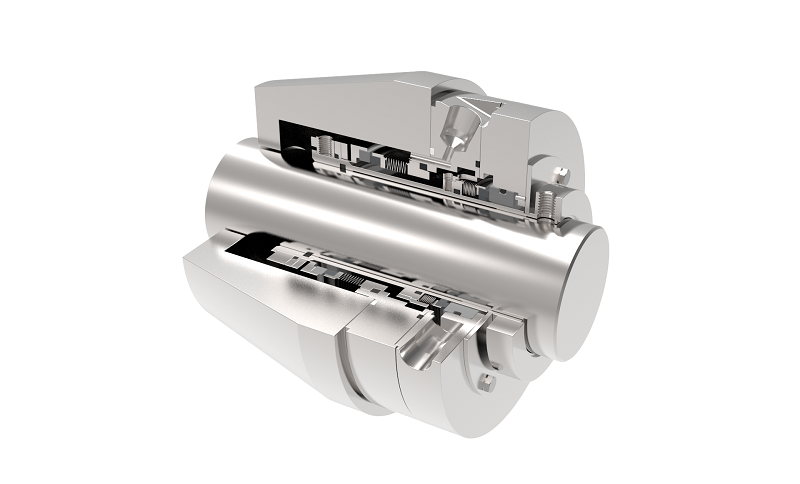

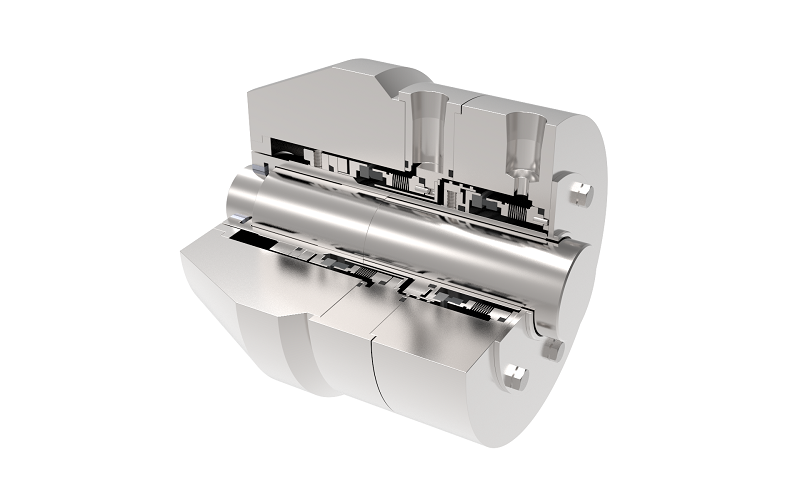

SCBT3

The Double, Tandem, Balanced and Welded Stationary Metal Bellows Seal designs are used to oil refining, petrochemistry and chemical industry. it is less sensitive for Alignment or Perpendicularity since use the Stationary Bellows Seal. it is used to high speed. also perfectly comply Arrangement 3 of API 682 Type A. it use the Pumping Ring to the Out Part Rotor for circulate the Sealant.

-

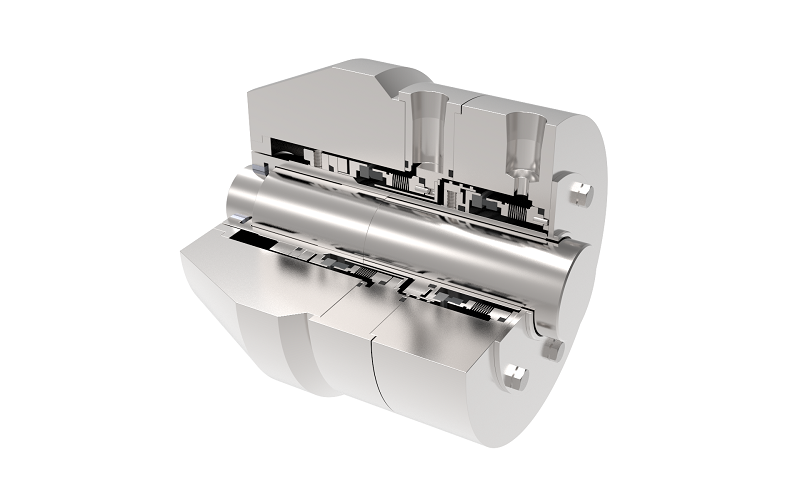

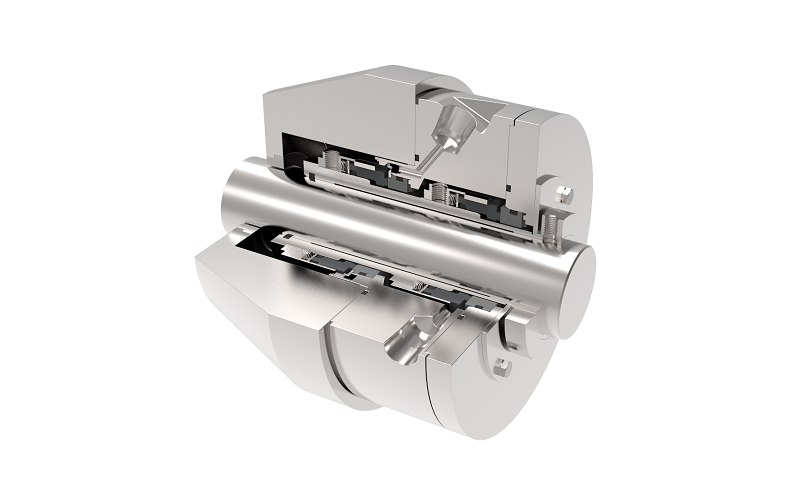

SCBT4

The Double, Tandem, Balanced and Welded Stationary Alloy 718 Bellows Seal are used to the high temperature petrochemical equipment. these are perfectly comply Arrangement 3 of API 682 Type A. it use an Alloy 718 material and a Low Stress Bellows design to improve the corrosion resistance. it is less sensitive for Alignment or Perpendicularity since use the Stationary Bellows Seal. it is used to high speed. also it use the Screw Ring to the Out Part Rotor for circulate the Sealant. -

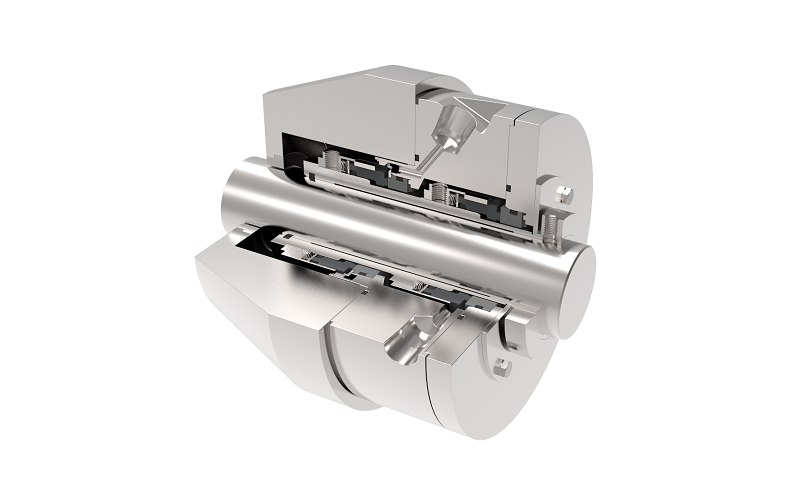

CS7MT

The CS7MT is designed to withstand the Inversion Phenomenon of Pressure. it has a more wide limit of pressure and complies Arrangement 3 of API 682 Type A. it use the Pumping Ring to the Out Part Rotor for circulate the Sealant. -

CS8MT

The CS8MT is designed to withstand against the Inversion Phenomenon of Pressure. it has a more wide limit of pressure and complies Arrangement 3 of API 682 Type A.